ABSTRACT

The necessity to deliver cost

effective energy in the power market has become a major concern in this

emerging technology era. Therefore, establishing a desired power condition at

the given points are best achieved using power controllers such as the well-known

High Voltage Direct Current (HVDC) and Flexible Alternating Current

Transmission System (FACTS) devices. High Voltage Direct Current (HVDC) is used

to transmit large amounts of power over long distances. The factors to be considered

are Cost, Technical Performance and Reliability. A Flexible Alternating Current

Transmission System (FACTS) is a system composed of static equipment used for the

AC transmission of electrical energy. It is meant to enhance controllability

and increase power transfer capability of the network. It is generally power

electronics based system. A Unified Power Flow Controller (or UPFC) is a FACTS

device for providing fast-acting reactive power compensation on high-voltage

electricity transmission networks. The UPFC is a versatile controller which can

be used to control active and reactive power flows in a transmission line. The focus of this paper is to identify the improved

Power Transmission Capability through control scheme and comprehensive analysis

for a Unified Power Flow Controller (UPFC) on the basis of theory, computer simulation.

The conventional control scheme cannot attenuate the power fluctuation, and so

the time constant of damping is independent of active- and reactive-power feedback

gains integrated in its control circuit. The model was analysed for different

types of faults at different locations, keeping the location of UPFC fixed at

the receiving end of the line, With the addition of UPFC, the magnitude of

fault current and oscillations of excitation voltage reduces. Series and Shunt

parts of UPFC provide series and shunt injected voltage at certain different

angles.

Index Terms –Flexible ac transmission system (FACTS), High-voltage dc transmission

(HVDC), FACTS devices, Power transfer controllability, PWM, Faults in HVDC

System.

CHAPTER 1

I.INTRODUCTION

The rapid development of power systems

generated by increased demand for electric energy initially in industrialized countries

and subsequently in emerging countries led to different technical problems in

the systems, e.g., stability limitations and voltage problems. However,

breaking Innovations in semiconductor technology then enabled the manufacture

of powerful thermistor’s and, later of new elements such as the gate turn-off thermistor’s

(GTO) and insulated gate bipolar transistors (IGBT). Development based on these

semiconductor devices first established high-voltage dc transmission (HVDC)

technology as an alternative to long distance ac transmission. HVDC technology,

in turn, has provided the basis for the development of flexible ac Transmission

system (FACTS) equipment which can solve problems in ac transmission. As a

result of deregulation, however, Operational problems arise which create

additional requirements for load flow control and needs for ancillary services

in the system. This paper summarizes Flexible ac transmission system

(FACTS),High-Voltage DC Transmission (HVDC), FACTS devices, Power transfer

controllability, Fault in HVDC System are discussed in this paper to explain

how greater performance of power network transmission with various line

reactance can be achieved.[1,2].

(a) Reduced maintenance

(b) Better availability

(c) Greater reliability

(d) Increased power

(e) Reduced losses

(f) Cost-effectiveness

During the state of power exchange in

interconnected lines to a substation under variable or constant power, the HVDC

converters comprehends the power conversion and later stabilizes the voltage

through the lines giving a breakeven margin in the power transmission. The

first large scale Thyristor’s for HVDC were developed decades ago. HVDC became

a conventional technology in the area of back to- back and two- terminal

long-distance and submarine cable schemes [3]. However, only few multi terminal

schemes have been realized up to now. However, further multi terminal HVDC

schemes are planned in the future (Fig. 1). The main application area for HVDC

is the interconnection between systems which cannot be interconnected by AC

because of different operating frequencies or different frequency controls. This

type of interconnection is mainly represented by back-to-back stations or

long-distance transmissions when a large amount of power, produced by a

hydropower plant, for instance, has to be transmitted by overhead line or by submarine

cable. HVDC schemes to increase power transmission capability inside of a

system have been used only in a few cases in the past. However, more frequent

use of such HVDC applications can be expected in the future to full-fill the requirements

in deregulated.[4,6]. Fig 1 various types of HVDC Connections Static var

compensators control only one of the three important parameters (voltage,

impedance, phase angle) determining the power flow in ac power systems: the amplitude

of the voltage at selected terminals of the transmission line. Theoretical

considerations and recent system studies (1) indicate that high utilization of

a complex, Interconnected ac power system, meeting the desired objectives for

availability and operating flexibility, may also require the real time control

of the line impedance and the phase angle. Hingorani (2) proposed the concept of

flexible ac transmission systems or FACTS, which

includes the use of high power electronics, advanced control centres,

and communication links, to increase the usable power transmission capacity to

its thermal limit. [5].

When using carrier based Pulse Width Modulation

(PWM), its switching frequency has to be increased (typically, 33 times

fundamental frequency even higher [17], which cause considerable power losses.

It reduces the total efficiency and economy of the UPFC-HVDC project. And they

are also the Impediments for equipment aimed at the green, renewable Sector.

Therefore, with regard to PWM technology suited for UPFC-HVDC, how to reduce

switching frequency and possess good harmonics performance, excellent transient

control capability simultaneously become critical. And this is exactly the aim

of the paper. The paper presents an innovative hybrid PWM technology, which

comprises a combination of a first PWM with a first switching pattern and a

second PWM with a second switching pattern. Hence during a first mode of operation,

which may be a steady-state operation, the converter is controlled by the first

PWM and during a second mode of operation, which may be a transient operation,

the converter is controlled by the second PWM. An intelligent detection

function which enables the modulation and the corresponding control system will

smoothly switch from the first PWM to the second PWM and vice-versa when a disturbance

causing a transient occurs. The development of FACTS-devices has started with the

growing capabilities of power electronic components. Devices for high power

levels have been made available in converters for high and even highest voltage

levels. The overall starting points are network elements influencing the reactive

power or the impedance of a part of the power system. The series devices are

compensating reactive power. With their influence on the effective impedance on

the line they have an influence on stability and power flow. The UPFC provides

power flow control together with independent voltage control [7, 8].

CHAPTER 2

HIGH VOLTAGE

DC TRANSMISSION SYSTEM

Over long distances bulk power transfer can be carried out by a high

voltage direct current (HVDC) connection cheaper than by a long distance AC

transmission line. HVDC transmission

can also be used where an AC transmission scheme could not (e.g. through very

long cables or across borders where the two AC systems are not synchronized or

operating at the same frequency). However, in order to achieve these long

distance transmission links, power convertor equipment is required, which is a

possible point of failure and any interruption in delivered power can be

costly. It is therefore of critical importance to design a HVDC scheme for a

given availability.

The HVDC

technology is a high power electronics technology used in electric power

systems. It is an efficient and flexible method to transmit large amounts of

electric power over long distances by overhead transmission lines or

underground/submarine cables. It can also be used to interconnect asynchronous

power systems

The fundamental process that occurs

in an HVDC system is the conversion of electrical current from AC to DC (rectifier) at the

transmitting end and from DC to AC (inverter) at the receiving end.

There are three ways of achieving

conversion

1.

Natural commutated converters

2.

Capacitor Commutated Converters

3.

Forced Commutated Converters

2.1 NATURAL COMMUTATED CONVERTERS: (NCC)

NCC are most used in the

HVDC systems as of today. The component that enables this conversion process is

the thyristor, which is a

controllable semiconductor that can carry very high currents (4000 A) and is able to block very high

voltages (up to 10 kV). By means of

connecting the thyristors in series it is possible to build up a thyristor

valve, which is able to operate at very high voltages (several hundred of kV).The thyristor valve is operated at net

frequency (50 Hz or 60 Hz) and by means of a control angle it is possible to

change the DC voltage level of the bridge..

2.2 CAPACITOR COMMUTATED CONVERTERS: (CCC)

An improvement in the Thyristor-based

Commutation, the CCC concept is characterized by the use of commutation

capacitors inserted in series between the converter transformers and the Thyristor

valves. The commutation capacitors

improve the commutation failure performance of the converters when connected to

weak networks.

2.3 FORCED COMMUTATED CONVERTERS: (FCC)

This type of converters

introduces a spectrum of advantages, e.g. feed of passive networks (without

generation), independent control of active and reactive power, power quality.

The valves of these converters are built up with semiconductors with the

ability not only to turn-on but also to

turn-off. They are known as VSC (Voltage Source Converters). a new type of HVDC has become available. It

makes use of the more advanced semiconductor technology instead of Thyristor’s

for power conversion between AC and DC. The semiconductors used are insulated

gate bipolar transistors (IGBTs), and the converters are voltage source

converters (VSCs) which operate with high switching frequencies (1-2 kHz)

utilizing pulse width modulation (PWM).

2.4 CONFIGURATIONS

OF HVDC:

There are different types of HVDC

systems

Such as:

Mono-polar HVDC system

In the mono-polar configuration, two

converters are connected by a single pole line and a positive or a negative DC

voltage is used. In Fig 2.1 there is only one Insulated transmission conductor

installed and the ground or sea provides the path for the return current.

Fig 2.1: Mono

polar HVDC system

Bipolar HVDC

system:

This is the

most commonly used configuration of HVDC transmission systems. The bipolar

configuration shown in Fig 2.2 uses two insulated conductors as Positive and

negative poles. The two poles can be operated independently if both Neutrals

are grounded. The bipolar configuration increases the power transfer capacity.

Under normal

operation, the currents flowing in both poles are identical and there is no

ground current. In case of failure of one pole power transmission can continue

in the other pole which increases the reliability. Most overhead line HVDC

transmission systems use the bipolar configuration.

Fig2.2: Bipolar HVDC system

Homo-polar HVDC system:

In the homo polar configuration as shown in Fig2.3 two or more conductors have the negative polarity and can be operated with ground or a metallic return. With two Poles operated in parallel, the Homo-polar configuration reduces the insulation costs. However, the large earth return current is the major disadvantage.

Fig2.3:

Homo-polar HVDC system

2.5 MULTI-TERMINAL HVDC SYSTEM:

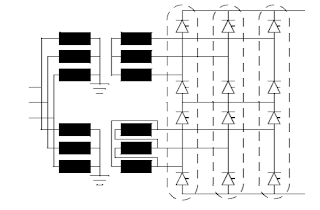

In the multi terminal

configuration, three or more HVDC converter stations are geographically

separated and interconnected through transmission lines or cables. The System

can be either parallel, where all converter stations are connected to the same

voltage as shown in Fig(b). or series

multi-terminal system, where one or more converter stations are connected in

series in one or both poles as shown in Fig. (c). A hybrid multi-terminal

system contains a combination of parallel and series connections of converter

stations

Fig 2.4: multi-terminal HVDC system

2.6 voltage-source converter:

A voltage-source converter

is connected on its ac-voltage side to a three-phase electric power network via

a transformer and on its dc-voltage side to capacitor equipment. The

transformer has on its secondary side a first, a second, and a third phase

winding, each one with a first and a second winding terminal. Resistor

equipment is arranged at the transformer for limiting the current through the

converter when connecting the transformer to the power network. The resistor

equipment includes a first resistor, connected to the first winding terminal of

the second phase winding, and switching equipment is adapted, in an initial

position, to block current through the phase windings, in a transition position

to form a current path which includes at least the first and the second phase windings

and, in series therewith, the first resistor, which current path, when the

converter is connected to the transformer, closes through the converter and the

capacitor equipment, and, in an operating position, to interconnect all the

first winding terminals for forming the common neutral point.

In VSC HVDC, Pulse Width Modulation (PWM) is used for generation of

the fundamental voltage. Using PWM, the magnitude and phase of the voltage can

be controlled freely and almost instantaneously within certain limits.

This allows independent and very fast control of active and reactive power

flows. PWM VSC is therefore a close to ideal component in the transmission

network. From a system point of view, it acts as a zero inertia motor or

generator that can control active and reactive power almost instantaneously.

Furthermore, it does not contribute to the short-circuit power, as the AC

current can be controlled.

Voltage Source Converter based on IGBT technology:

The modular low voltage power electronic platform is called Power-Pack.

It is a power electronics building block (PEBB) with three integrated Insulated

Gate Bipolar Transistor (IGBT) modules. Each IGBT module consists of six

switches forming three phase legs. Various configurations are possible. For

example three individual three-phase bridges on one PEBB, one three phase

bridge plus chopper(s) etc. The Power-Pack is easily adaptable for different

applications.

The IGBT modules used are one Power Pak as it is used for the SVR.

It consists of one three-phase bridge (the three terminals at the right hand

side), which provides the input to the DC link (one IGBT module is used for it)

and one output in form of one single phase H-bridge (the two terminals to the

left) acting as the booster converter. For the latter two IGBT modules are used

with three paralleled phase legs per output terminal. By paralleling such PEBBs

adaptation to various ratings is possible.

GTO/IGBT (Thyristor based HVDC):

Normal

Thyristor’s (silicon controlled rectifiers) are not fully controllable switches

(a "fully controllable switch" can be turned on and off at will.) Thyristor’s

can only be turned ON and cannot be turned OFF. Thyristor’s are switched ON by

a gate signal, but even after the gate signal is de-asserted (removed), the Thyristor

remains in the ON-state until any turn-off condition occurs (which can

be the application of a reverse voltage to the terminals, or when the

current flowing through (forward current) falls below a certain threshold value

known as the holding current.) Thus, a Thyristor behaves like a normal

semiconductor diode after it is turned on or "fired".

The GTO can be turned-on by a gate signal, and can also be turned-off

by a gate signal of negative polarity.

Turn on is accomplished by a positive

current pulse between the gate and cathode terminals. As the gate-cathode

behaves like PN junction, there will be some relatively small voltage between

the terminals. The turn on phenomenon in GTO is however, not as reliable as an

SCR (Thyristor) and small positive gate current must be maintained even after

turn on to improve reliability.

Turn off is accomplished by a negative

voltage pulse between the gate and cathode terminals. Some of the forward

current (about one third to one fifth) is "stolen" and used to induce

a cathode-gate voltage which in turn induces the forward current to fall and

the GTO will switch off (transitioning to the 'blocking' state.)

GTO Thyristor’s suffer from long switch off times, whereby after the

forward current falls, there is a long tail time where residual current

continues to flow until all remaining charge from the device is taken away.

This restricts the maximum switching frequency to approx. 1 kHz.

It may however be noted that the turn off time of a comparable SCR

is ten times that of a GTO. Thus

switching frequency of GTO is much better than SCR.

Gate turn-off (GTO) thyristors are used not only to turn on the main

current but also to turn it off, provided with a gate drive circuit. Unlike

conventional thyristors, they have no commutation circuit, downsizing

application systems while improving efficiency. They are the most suitable for

high-current, high speed switching applications, such as inverters and chopper

circuits.

Bipolar devices made with SiC offer 20-50X lower switching losses as

compared to conventional semiconductors. A rough estimate of the switching

power losses as a function of switching frequency is shown in Figure 4. Another

very significant property of SiC bipolar devices is their lower differential

on-state voltage drop than similarly rated Si bipolar device, even with order

of magnitude smaller carrier lifetimes in the drift region.

This property allows high voltage (>20 kV) to be far more

reliable and thermally stable as compared to those made with Silicon. The

switching losses and the temperature stability of bipolar power devices depend

on the physics of operation of the device.

The two major categories of

bipolar power devices are: (a) single injecting junction devices (for example

BJT and IGBT); and (b) double injecting junction devices (like Thyristor-based

GTO/MTO/JCT/FCT and PIN diodes). In a power BJT, most of the minority carrier

charge resides in the low doped collector layer, and hence its operation has

been approximated as an IGBT. The limited gain of a BJT will make the following

analysis less relevant for lower voltage devices.

Silicon carbide has been

projected to have tremendous potential for high voltage solid-state power

devices with very high voltage and current ratings because of its electrical

and physical properties. The rapid development of the technology for producing

high quality single crystal [SiC] wafers and thin films presents the

opportunity to fabricate solid- state devices with power-temperature capability

far greater than devices currently available. This capability is ideally suited

to the applications of power conditioning in new more- electric or all-electric

military and commercial vehicles.

These applications require switches and amplifiers capable of large

currents with relatively low voltage drops. One of the most pervasive power

devices in silicon is the Insulated Gate Bipolar Transistor (IGBT). However,

these devices are limited in their operating temperature and their achievable

power ratings compared to that possible with [SiC]. Because of the nearly ideal

combination of characteristics of these devices, we propose to demonstrate the

first 4H-SiC Insulated Gate Bipolar Transistor in this Phase I effort. Both

n-channel and p-channel SiC IGBT devices will be investigated. The targeted

current and voltage rating for the Phase I IGBT will be a >200 Volt, 200 mA

device, that can operate at 350 C.

12-Pulse Converters:

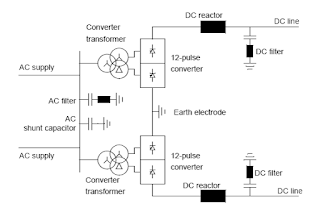

The basic design for practically all HVDC converters is the 12-pulse

double bridge converter which is shown in Figure below. The converter consists

of two 6-pulse bridge converters connected in series on the DC side. One of

them is connected to the AC side by a YY-transformer, the other by a YD

transformer. The AC currents from each 6-pulse converter will then be phase

shifted 30°. This will reduce the harmonic content in the total current drawn

from the grid, and leave only the characteristic harmonics of order 12 m±1,

m=1,2,3..., or the 11th, 13th, 23th, 25th etc. harmonic. The non-characteristic

harmonics will still be present, but considerably reduced. Thus the need for

filtering is substantially reduced, compared to 6-pulse converters. The

12-pulse converter is usually built up of 12 thyristor valves. Each valve consists

of the necessary number of thyristors in series to withstand the required

blocking voltage with sufficient margin. Normally there is only one string of

thyristors in each valve, no parallel connection. Four valves are built

together in series to form a quadruple valve and three quadruple valves,

Fig 2.5: 12-pulse converter.

Fig 2.6: two 12 pulse converter

Main elements of a HVDC

converter station with one bipolar consisting of two

12-pulse converter unit.

Together with

converter transformer, controls and protection equipment constitute a

converter. The converter transformers are usually three winding transformers

with the windings

in Yy d N-connection. There can be one three-phase or three single phase

transformers, according to local circumstances. In order to optimize the

relationship between AC- and DC voltage the converter transformers are equipped

with tap changers.

HVDC

converter stations

An HVDC

converter station is normally built up

of one or two 12-pulse converters as described above, depending on the system

being mono- or bipolar. In some cases each pole of a bipolar system consists of

two converters in series to increase the voltage and power rating of the

transmission. It is not common to connect converters directly in parallel in

one pole. The poles are normally as independent as possible to improve the

reliability of the system, and each pole is equipped with a DC reactor and DC

filters. Additionally the converter station consists of some jointly used

equipment.

This can be

the connection to the earth electrode, which normally is situated some distance

away from the converter station area, AC filters and equipment for supply of

the necessary reactive power.

Fig 2.7: Mono-polar HVDC transmissions

Voltage in station B according to reversed polarity convention.

CHAPTER

3

BASIC

CONTROL PRINCIPLES

3.1 CONTROL

SYSTEM MODEL:

The control model mainly consists of measurements and generation of

firing signals for both the rectifier and inverter. The PLO is used to build

the firing signals. The output signal of the PLO is a ramp, synchronized to the

phase-A commutating bus line-to-ground voltage, which is used to generate the

firing signal for Valve 1. The ramps for other valves are generated by adding

60 to the Valve 1 ramp. As a result, an equidistant pulse is realized. The

actual firing time is calculated by comparing the order to the value of the

ramp and using interpolation technique. At the same time, if the valve

is pulsed but its voltage is still less than the forward voltage drop, this

model has a logic to delay firing until the voltage is exactly equal to the

forward voltage drop. The firing pulse is maintained across each valve for 120.

The measurement circuits use zero-crossing information from

commutating bus voltages and valve switching times and then convert this time

difference to an angle (using measured PLO frequency). Firing angle (in

seconds) is the time when valve turns on minus the zero crossing time for

valve.

Extinction angle (in seconds) for valve is the time at which the

commutation bus voltage for valve crosses zero (negative to positive) minus the time valve turns off.

The control schemes for both rectifier and inverter of the CIGRÉ HVDC system

are available in the example file in PSCAD/EMTDC Version 4.0.1.

Following are the controllers used in the control schemes:

•

Extinction Angle Controller;

• dc

Current Controller;

• Voltage

Dependent Current Limiter (VDCOL).

Rectifier Control: The

rectifier control system uses Constant Current Control (CCC) technique. The

reference for current limit is obtained from the inverter side. This is done to

ensure the protection of the converter in situations when inverter side does

not have sufficient dc voltage support (due to a fault) or does not have

sufficient load requirement (load rejection). The reference current used in

rectifier control depends on the dc voltage available at the inverter side. Dc

current on the rectifier side is measured using proper transducers and passed

through necessary filters before they are compared to produce the error signal.

The error signal is then passed through a PI controller, which produces the

necessary firing angle order. The firing circuit uses this information to

generate the equidistant pulses for the valves using the technique described

earlier.

Inverter Control: The Extinction Angle Control or control

and current control have been implemented on the inverter side. The CCC with

Voltage Dependent Current Order Limiter (VDCOL) has been used here through PI

controllers. The reference limit for the current control is obtained through a

comparison of the external reference (selected by the operator or load

requirement) and VDCOL (implemented through lookup table) output. The measured

current is then subtracted from the reference limit to produce an error signal

that is sent to the PI controller to produce the required angle order.

The control uses another PI

controller to produce gamma angle order for the inverter. The two angle orders

are compared, and the minimum of the two is used to calculate the firing

instant.

3.2

SIMULINK CONTROL SYSTEM MODEL:

The control

blocks available in SIMULINK have been used to emulate the control algorithm

described above Section, and enough care has been taken. Some control

parameters required conversion to their proper values due to differences in

units. The rectifier side uses current control with a reference obtained from

the inverter VDCOL output (implemented through a lookup table), and the

inverter control has both current control and control operating in parallel,

and the lower output of the two is used to generate the firing pulses. The

angle is not provided directly from the converter valve data. It needed to be

implemented through measurements taken from valve data. The control block

diagrams are shown in Fig.

Fig 3.1: Simulink Model for sag, swell and 7th harmonic

Fig 3.2: Simulink model for pi controller

Fig 3.3: Addition of sag and swell

3.3 DC transmission

control

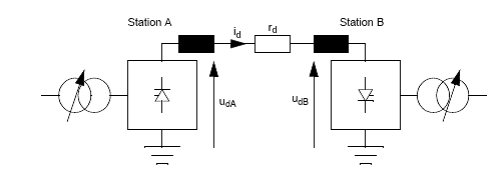

The current

flowing in the DC transmission line shown in Figure below is determined by the

DC voltage difference between station A and station B. Using the notation shown

in the figure, where rd represents the total resistance of the line, we

get for the DC current is

In rectifier

operation the firing angle α should not be decreased below a certain minimum

value αmin, normally 3°-5° in order to make sure that there really is a

positive voltage across the valve at the firing instant. In inverter operation

the extinction angle should never decrease below a certain minimum value γmin,

normally 17°-19° otherwise the risk of commutation failures becomes too high.

On the other hand, both α and γ should be as low as possible to keep the

necessary nominal rating of the equipment to a minimum. Low values of α and γ

also decrease the consumption of reactive power and the harmonic distortion in

the AC networks.

To achieve

this, most HVDC systems are controlled to maintain γ = γmin in

normal operation. The DC voltage level is controlled by the transformer tap

changer in inverter station B. The DC current is controlled by varying the DC

voltage in rectifier station A, and thereby the voltage difference between A

and B. Due to the small DC resistances in such a system, only a small voltage

difference is required, and small variations in rectifier voltage gives large

variations in current and transmitted power. The DC current through a converter

cannot change the direction of flow. So the only way to change the direction of

power flow through a DC transmission line is to reverse the voltage of the

line. But the sign of the voltage difference has to be kept constantly positive

to keep the current flowing. To keep the firing angle ‘α’ as low as possible,

the transformers tap changer in rectifier station A is operated to keep ‘α’ on

an operating value which gives only the necessary margin to αmin to be able to

control the current.

3.4 CONVERTER CURRENT/VOLTAGE CHARACTERISTICS:

The resistive voltage drop in converter and transformer, as well as

the non-current voltage drop in the thyristor valves are often disregarded in

practical analysis, as they are normally in the magnitude of 0.5 % of the

normal operating voltage. The commutation voltage drop, however, has to be

taken into account because its magnitude 5 to 10 % of the normal operating

voltage. The direct voltage Ud from a 6-pulse bridge converter can then

be expressed by

Where α is the

firing angle, If the converter is operating as inverter it is more convenient

to operate with extinction angle γ instead of firing angle α. The extinction

angle is defined as the angle between the end of commutation to the next zero

crossing of the commutation voltage. Firing angle α, commutation angle μ and

extinction angle γ are related by

In inverter

mode, the direct voltage from the inverter can be written as

The

current/voltage characteristics expressed in above are shown for normal values

of id and dxN. In order to create a characteristic diagram for

the complete transmission, it is usual to define positive voltage in inverter

operation in the opposite direction compared to rectifier operation.

It is clear

that to operate both converters on a constant firing/extinction angle principle

is like leaving them without control. This will not give a stable point of

operation, as both characteristics have approximately the same slope. Small

differences appear due to variations in transformer data and voltage drop along

the line. To gain the best possible control the characteristics should cross at

as close to a right angle as possible. This means that one of the

characteristics should preferably be constant current. This can only be

achieved by a current controller.

If the

current/voltage diagram of the rectifier is combined with a constant current

controller characteristic we get the steady state diagram in Figure below for

converter station A. A similar diagram can be drawn for converter station B. If

we apply the reversed polarity convention for the inverter and combine the

diagrams for station A and station B we get the diagram in Figure below in

normal operation, the rectifier will be operating in current control mode with

the firing angle

Fig 3.4: Steady state ud/id diagram for

converter station A Steady state ud/id diagram

for converter station A&B

The inverter has a slightly lower current command than the rectifier

and tries to decrease the current by increasing the counter voltage, but cannot

decrease γ beyond γmin. Thus we get the operating point A. We

assume that the characteristic for station B is referred to station A i.e. it

is corrected for the voltage drop along the transmission line. This voltage

drop is in the magnitude of 1-5 % of the rated DC voltage.

If the AC voltage at the rectifier station drops, due to some

external disturbance, the voltage difference is reduced and the DC current

starts to sink. The current controller in the rectifier station starts to

reduce the firing angle α, but soon meets the limit αmin, so the current

cannot be upheld. When the current sinks below the current command of the

inverter, the inverter control reduces the counter voltage to keep the current

at the inverter current command, until a new stable operating point B is

reached. If the current command at station A is decreased below that of station

B, station A will see a current that is too high and start to increase the

firing angle ‘α’, to reduce the voltage. Station B will see a diminishing

current and try to keep it up by increasing the extinction angle γ to reduce

the counter voltage. Finally station A meets the γmin limit

and cannot reduce the voltage any further and the new operating point will be

at point C. Here the voltage has been reversed to negative while the current is

still positive, that is the power flow has been reversed. Station A is operating

as inverter and station B as rectifier. The difference between the current

commands of the rectifier and the inverter is called the current margin. It is

possible to change the power flow in the transmission simply by changing the

sign of the current margin, but in practice it is desirable to do this in more

controllable ways. Therefore the inverter is normally equipped with a αmin limitation

in the range of 95°-105°. To avoid current fluctuations between operating

points A and B at small voltage variations the corner of the inverter

characteristic is often cut off. Finally, it is not desirable to operate the

transmission with high currents at low voltages, and most HVDC controls are

equipped with voltage dependent current command limitation.

3.3

MASTER CONTROL SYSTEM:

The controls described above are basic and fairly standardized and

similar for all HVDC converter stations. The master control, however, is

usually system specific and individually designed. Depending on the

requirements of the transmission, the control can be designed for constant

current or constant power transmitted, or it can be designed to help

stabilizing the frequency in one of the AC networks by varying the amount of

active power transmitted. The control systems are normally identical in both

converter systems in a transmission, but the master control is only active in

the station selected to act as the master station, which controls the current

command. The calculated current command is transmitted by a communication

system to the slave converter station, where the pre-designed current margin is

added if the slave is to act as rectifier, subtracted if it is to act as

inverter. In order to synchronize the two converters and assure that they

operate with same current command (apart from the current margin), a

tele-communications channel is required.

Should the telecommunications system fail for any reason, the

current commands to both converters are frozen, thus allowing the transmission

to stay in operation. Special fail-safe techniques are applied to ensure that

the telecommunications system is fault-free. The requirements for the

telecommunications system are especially high if the transmission is required

to have a fast control of the transmitted power, and the time delay in

processing and transmitting these signals will influence the dynamics of the

total control system.

Conclusion of

Different HVAC-HVDC

In

order to examine the behavior of the losses in combined transmission and not in

order to provide the best economical solutions for real case projects. Thus,

most of the configurations are overrated, increasing the initial investment

cost and consequently the energy transmission cost. The small number of

different configurations analyzed provides a limited set of results, from which

specific conclusions can be drawn regarding the energy transmission cost.

Nevertheless, the same approach, as for the individual HVACHVDC systems, is

followed in order to evaluate the energy availability and the energy

transmission cost.

CHAPTER 4

UNIFIED POWER FLOW CONTROLLER

4.1 INTRODUCTION:

Flexible AC Transmission Systems, called FACTS, got in the recent

years a well-known term for higher controllability in power systems by means of

power electronic devices. Several FACTS-devices have been introduced for

various applications worldwide. A number of new types of devices are in the

stage of being introduced in practice.

In most of the applications the controllability is used to avoid

cost intensive or landscape requiring extensions of power systems, for instance

like upgrades or additions of substations and power lines. FACTS-devices

provide a better adaptation to varying operational conditions and improve the

usage of existing installations. The basic applications of FACTS-devices are:

• Power flow control,

• Increase of transmission capability,

• Voltage control,

• Reactive power compensation,

• Stability improvement,

• Power quality improvement,

• Power conditioning,

• Flicker mitigation,

• Interconnection of renewable and distributed generation and

storages.

Operational limits of transmission line:

Figure 4.1 shows the basic idea of FACTS for transmission systems.

The usage of lines for active power transmission should be ideally up to the

thermal limits. Voltage and stability limits shall be shifted with the means of

the several different FACTS devices. It can be seen that with growing line

length, the opportunity for FACTS devices gets more and more important.

The influence of FACTS-devices is achieved through switched or

controlled shunt compensation, series compensation or phase shift control. The

devices work electrically as fast current, voltage or impedance controllers.

The power electronic allows very short reaction times down to far below one

second.

Fig 4.1: operational limits of transmission lines for

different levels

The development of FACTS-devices has started with the growing

capabilities of power electronic components. Devices for high power levels have

been made available in converters for high and even highest voltage levels. The

overall starting points are network elements influencing the reactive power or

the impedance of a part of the power system. Figure 4.2 shows a number of basic

devices separated into the conventional ones and the FACTS-devices.

For the FACTS side the taxonomy in terms of 'dynamic' and 'static'

needs some explanation. The term 'dynamic' is used to express the fast

controllability of FACTS-devices provided by the power electronics. This is one

of the main differentiation factors from the conventional devices. The term

'static' means that the devices have no moving parts like mechanical switches

to perform the dynamic controllability. Therefore most of the FACTS-devices can

equally be static and dynamic.

Fig 4.2: overview

of major FACTS- Devices

The left column in Figure 4.2 contains the conventional devices build

out of fixed or mechanically switch able components like resistance, inductance

or capacitance together with transformers. The FACTS-devices contain these

elements as well but use additional power electronic valves or converters to

switch the elements in smaller steps or with switching patterns within a cycle

of the alternating current. The left column of FACTS-devices uses Thyristor

valves or converters. These valves or converters are well known since several

years. They have low losses because of their low switching frequency of once a

cycle in the converters or the usage of the Thyristor’s to simply bridge

impedances in the valves.

The right column of FACTS-devices contains more advanced technology

of voltage source converters based today mainly on Insulated Gate Bipolar

Transistors (IGBT) or Insulated Gate Commutated Thyristor’s (IGCT). Voltage

Source Converters provide a free controllable voltage in magnitude and phase

due to a pulse width modulation of the IGBTs or IGCTs. High modulation

frequencies allow to get low harmonics in the output signal and even to

compensate disturbances coming from the network. The disadvantage is that with

an increasing switching frequency, the losses are increasing as well. Therefore

special designs of the converters are required to compensate this transmission

line.

4.2 SHUNT

DEVICES:

The most used FACTS-device is the SVC or the version with Voltage

Source Converter called STATCOM. These shunt devices are operating as reactive

power compensators. The main applications in transmission, distribution and

industrial networks are:

• Reduction of unwanted reactive power flows and therefore reduced

network losses.

• Keeping of contractual power exchanges with balanced reactive

power.

• Compensation of consumers and improvement of power quality

especially with huge demand fluctuations like industrial machines, metal

melting plants, railway or underground train systems.

• Compensation of Thyristor converters e.g. in conventional HVDC

lines.

• Improvement of static or transient stability.

Almost half of the SVC and more than half of the STATCOMs are used

for industrial applications. Industry as well as commercial and domestic groups

of users require power quality. Flickering lamps are no longer accepted, nor

are interruptions of industrial processes due to insufficient power quality.

Railway or underground systems with huge load variations require SVCs or

STATCOMs.

Static VAR compensator (svc):

Electrical loads both generate and absorb reactive power. Since the

transmitted load varies considerably from one hour to another, the reactive

power balance in a grid varies as well. The result can be unacceptable voltage

amplitude variations or even a voltage depression, at the extreme a voltage

collapse.

A rapidly operating Static VAR Compensator (SVC) can continuously

provide the reactive power required to control dynamic voltage oscillations

under various system conditions and thereby improve the power system

transmission and distribution stability.

Applications of the SVC systems in transmission systems:

Ø

To increase active power

transfer capacity and transient stability margin

Ø

To damp power oscillations

Ø

To achieve effective voltage

control

In addition, SVCs are also used in

1. Transmission

systems

Ø

To reduce temporary over

voltages

Ø

To damp sub synchronous

resonances

Ø

To damp power oscillations in

interconnected power systems

2. Traction

systems

Ø

To balance loads

Ø

To improve power factor

Ø

To improve voltage regulation

3. HVDC

systems

Ø To provide reactive power to ac–dc converters

4. Arc

furnaces

Ø To reduce voltage variations and associated light flicker

Installing an SVC at one or more suitable points in the network can

increase transfer capability and reduce losses while maintaining a smooth

voltage profile under different network conditions. In addition an SVC can

mitigate active power oscillations through voltage amplitude modulation.

SVC installations consist of a number of building blocks. The most

important is the Thyristor valve, i.e. stack assemblies of series connected

anti-parallel Thyristors to provide controllability. Air core reactors and high

voltage AC capacitors are the reactive power elements used together with the

Thyristor valves. The step up connection of this equipment to the transmission

voltage is achieved through a power transformer.

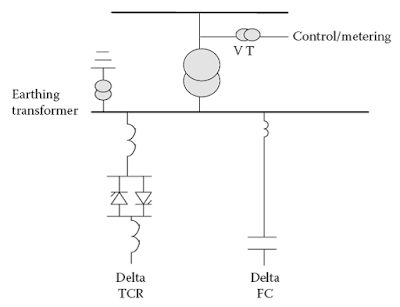

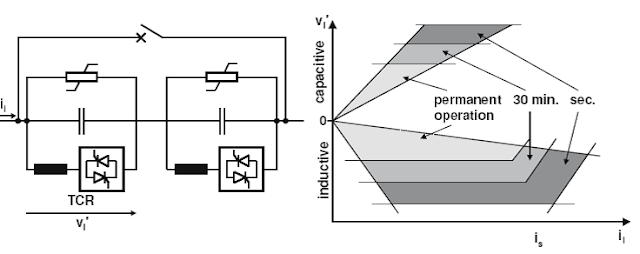

Fig 4.3: SVC building blocks and voltage / current

characteristic

In principle the SVC consists of Thyristor Switched Capacitors (TSC)

and Thyristor Switched or Controlled Reactors (TSR / TCR). The coordinated

control of a combination of these branches varies the reactive power as shown

in Figure. The first commercial SVC was installed in 1972 for an electric arc

furnace. On transmission level the first SVC was used in 1979. Since then it is

widely used and the most accepted FACTS-device.

SVC using a TCR and an fc:

In this arrangement, two or more FC (fixed capacitor) banks are

connected to a TCR (thyristor controlled reactor) through a step-down

transformer. The rating of the reactor is chosen larger than the rating of the

capacitor by an amount to provide the maximum lagging VARs that

have to be absorbed from the system. By changing the firing angle of the

thyristor controlling the reactor from 90° to 180°, the reactive power can be

varied over the entire range from maximum lagging VARS to leading

VARS that can be absorbed from the system by this compensator.

Fig 4.4: SVC of the FC/TCR type:

The main disadvantage of this configuration is the significant

harmonics that will be generated because of the partial conduction of the large

reactor under normal sinusoidal steady-state operating condition when the SVC

is absorbing zero MVAR. These harmonics are filtered in the following manner.

Triplex harmonics are canceled by arranging the TCR and the secondary windings

of the step-down transformer in delta connection. The capacitor banks with the

help of series reactors are tuned to filter fifth, seventh, and other

higher-order harmonics as a high-pass filter. Further losses are high due to

the circulating current between the reactor and capacitor banks.

Fig 4.5 Comparison of the loss characteristics of

TSC–TCR, TCR–FC compensators and synchronous condenser

These SVCs do not have a short-time overload capability because the

reactors are usually of the air-core type. In applications requiring overload

capability, TCR must be designed for short-time overloading, or separate

thyristor-switched overload reactors must be employed.

SVC using a TCR and TSC:

This compensator overcomes two major shortcomings of the earlier

compensators by reducing losses under operating conditions and better

performance under large system disturbances. In view of the smaller rating of

each capacitor bank, the rating of the reactor bank will be 1/n times the

maximum output of the SVC, thus reducing the harmonics generated by the

reactor. In those situations where harmonics have to be reduced further, a

small amount of FCs tuned as filters may be connected in parallel with the TCR.

Fig 4.6: SVC of combined TSC and TCR type

When large disturbances occur in a power system due to load

rejection, there is a possibility for large voltage transients because of

oscillatory interaction between system and the SVC capacitor bank or the parallel.

The LC circuit of SVC,in the FC compensator. In the TSC–TCR scheme, due to the

flexibility of rapid switching of capacitor banks without appreciable

disturbance to the power system, oscillations can be avoided, and hence the

transients in the system can also be avoided. The capital cost of this SVC is

higher than that of the earlier one due to the increased number of capacitor

switches and increased control complexity.

STATCOM:

In 1999 the first SVC with Voltage Source Converter called STATCOM

(Static VAR Compensator) went into operation. The STATCOM has a characteristic

similar to the synchronous condenser, but as an electronic device it has no

inertia and is superior to the synchronous condenser in several ways, such as

better dynamics, a lower investment cost and lower operating and maintenance

costs. A STATCOM is built with Thyristors with turn-off capability like GTO or

today IGCT or with more and more IGBTs. The static line between the current

limitations has a certain steepness determining the control characteristic for

the voltage.

The advantage of a STATCOM is that the reactive power provision is

independent from the actual voltage on the connection point. This can be seen

in the diagram for the maximum currents being independent of the voltage in

comparison to the SVC. This means, that even during most severe contingencies,

the STATCOM keeps its full capability.

In the distributed energy sector the usage of Voltage Source

Converters for grid interconnection is common practice today. The next step in

STATCOM development is the combination with energy storages on the DC-side. The

performance for power quality and balanced network operation can be improved

much more with the combination of active and reactive power.

Fig 4.7: STATCOM structure and voltage / current

characteristic

STATCOMs are based on Voltage Sourced Converter (VSC) topology and

utilize either Gate-Turn-off Thyristors (GTO) or Isolated Gate Bipolar

Transistors (IGBT) devices. The

STATCOM is a very fast acting, electronic equivalent of a synchronous

condenser. If the STATCOM voltage, Vs, (which is proportional to the dc bus

voltage Vc) is larger than bus voltage, Es, then leading or capacitive VARS are

produced. If Vs is smaller than Es, then lagging or inductive VARS is produced.

Fig 4.8: 6 Pulses

STATCOM

The three phases STATCOM makes use of the fact that on a three

phase, fundamental frequency, steady state basis, and the instantaneous power

entering a purely reactive device must be zero. The reactive power in each

phase is supplied by circulating the instantaneous real power between the

phases. This is achieved by firing the GTO/diode switches in a manner that

maintains the phase difference between the ac bus voltage ES and the STATCOM

generated voltage VS. Ideally it is possible to construct a device based on circulating

instantaneous power which has no energy storage device (ie no dc capacitor).

A practical STATCOM requires some amount of energy storage to

accommodate harmonic power and ac system unbalances, when the instantaneous

real power is non-zero. The maximum energy storage required for the STATCOM is

much less than for a TCR/TSC type of SVC compensator of comparable rating.

Fig 4.9: STATCOM Equivalent circuit

Several different control techniques can be used for the firing

control of the STATCOM. Fundamental switching of the GTO/diode once per cycle

can be used. This approach will minimize switching losses, but will generally

utilize more complex transformer topologies. As an alternative, Pulse Width

Modulated (PWM) techniques, which turn on and off the GTO or IGBT switch more

than once per cycle, can be used. This approach allows for simpler transformer

topologies at the expense of higher switching losses.

The 6 Pulse STATCOM using fundamental switching will of course

produce the 6 N+1 harmonics. There are a variety of methods to decrease the

harmonics. These methods include the basic 12 pulse configuration with parallel

star / delta transformer connections, a complete elimination of 5th and 7th

harmonic current using series connection of star/star and star/delta

transformers and a quasi-12 pulse method with a single star-star transformer,

and two secondary windings, using control of firing angle to produce a 30° phase

shift between the two 6 pulse bridges. This method can be extended to produce a

24 pulse and a 48 pulse STATCOM, thus eliminating harmonics even further.

Another possible approach for harmonic cancellation is a multi-level

configuration which allows for more than one switching element per level and

therefore more than one switching in each bridge arm. The ac voltage derived

has a staircase effect, dependent on the number of levels. This staircase

voltage can be controlled to eliminate harmonics.

4.3 SERIES DEVICES:

Series devices have been further developed from fixed or

mechanically switched compensations to the Thyristor Controlled Series

Compensation (TCSC) or even Voltage Source Converter based devices.

The main applications are:

Ø

Reduction of series voltage

decline in magnitude and angle over a

power line,

Ø

Reduction of voltage

fluctuations within defined limits during changing power transmissions,

Ø

Improvement of system damping

resp. damping of oscillations,

Ø

Limitation of short circuit

currents in networks or substations,

Ø

Avoidance of loop flows representation.

power flow adjustments.

TCSC:

Thyristor Controlled Series Capacitors (TCSC) addresses specific

dynamical problems in transmission systems. Firstly it increases damping when

large electrical systems are interconnected. Secondly it can overcome the

problem of Sub Synchronous Resonance (SSR), a phenomenon that involves an

interaction between large thermal generating units and series compensated

transmission systems.

The TCSC's high speed switching capability provides a mechanism for

controlling line power flow, which permits increased loading of existing

transmission lines, and allows for rapid readjustment of line power flow in

response to various contingencies. The TCSC also can regulate steady-state

power flow within its rating limits.as shown in fig 4.10

From a principal technology point of view, the TCSC resembles the

conventional series capacitor. All the power equipment is located on an

isolated steel platform, including the Thyristor valve that is used to control

the behavior of the main capacitor bank. Likewise the control and protection is

located on ground potential together with other auxiliary systems. Figure shows

the principle setup of a TCSC and its operational diagram. The firing angle and

the thermal limits of the Thyristors determine the boundaries of the

operational diagram.

Fig 4.10: a model

of TCR

Advantages

Ø Continuous control of desired compensation level

Ø Direct smooth control of power flow within the network

Ø Improved capacitor bank protection

Ø Local mitigation of sub synchronous resonance (SSR). This permits

higher levels of compensation in networks where interactions with

turbine-generator torsional vibrations or with other control or measuring

systems are of concern.

Ø Damping of electromechanical (0.5-2 Hz) power oscillations which

often arise between areas in a large interconnected power network. These

oscillations are due to the dynamics of inter area power transfer and often

exhibit poor damping when the aggregate power transfer over a corridor is high

relative to the transmission strength.

SSSC:

SSSC emulates like a variable inductor or capacitor in series with a

transmission line and it imitates inductance or capacitive reactance in turn to

regulate effective line reactance between two ends. Series controller in

general control current injection.

4.4 SHUNT AND SERIES DEVICES:

Dynamic power flow controller: A new device in the area of power flow control is the Dynamic Power

Flow Controller (DFC). The DFC is a hybrid device between a Phase Shifting

Transformer (PST) and switched series compensation.

A functional single line diagram of the Dynamic Flow Controller is shown

in Figure 4.12. The Dynamic Flow Controller consists of the following

components:

Ø

a standard phase shifting

transformer with tap-changer (PST)

Ø

series-connected Thyristor Switched

Capacitors and Reactors (TSC / TSR)

Ø

A mechanically switched shunt capacitor

(MSC). (This is optional depending on the system reactive power requirements)

Fig 4.11: Principle

Configuration of DFC

Based on the system requirements, a DFC might consist of a number of

series TSC or TSR. The mechanically switched shunt capacitor (MSC) will provide

voltage support in case of overload and other conditions. Normally the

reactance of reactors and the capacitors are selected based on a binary basis

to result in a desired stepped reactance variation. If a higher power flow resolution

is needed, a reactance equivalent to the half of the smallest one can be added.

The switching of series reactors occurs at zero current to avoid any

harmonics. However, in general, the principle of phase-angle control used in

TCSC can be applied for a continuous control as well. The operation of a DFC is

based on the following rules:

Ø

TSC / TSR are switched when a

fast response is required.

Ø

The decrease of overload and

work in stressed situations is handled by the TSC / TSR.

Ø

The switching of the PST tap-changer

should be minimized particularly for the currents higher than normal loading.

Ø

The total reactive power

consumption of the device can be optimized by the operation of the MSC, tap

changer, switched capacities and reactors.

In order to visualize the steady state operating range of the DFC,

we assume an inductance in parallel representing parallel transmission paths.

The overall control objective in steady state would be to control the

distribution of power flow between the branch with the DFC and the parallel

path. This control is accomplished by control of the injected series voltage.

The PST (assuming a quadrature booster) will inject a voltage in

quadrature with the node voltage. The controllable reactance will inject a

voltage in quadrature with the throughput current. Assuming that the power flow

has a load factor close to one, the two parts of the series voltage will be

close to collinear. However, in terms of speed of control, influence on

reactive power balance and effectiveness at high/low loading the two parts of

the series voltage has quite different characteristics. The steady state

control range for loadings up to rated current is illustrated in Figure 4.12,

where the x-axis corresponds to the throughput current and the y-axis

corresponds to the injected series voltage.

Fig 4.12: Operational diagram of

a DFC

Operation in the first and third quadrants corresponds to reduction

of power through the DFC, whereas operation in the second and fourth quadrants

corresponds to increasing the power flow through the DFC. The slope of the line

passing through the origin (at which the tap is at zero and TSC / TSR are

bypassed) depends on the short circuit reactance of the PST.

Starting at rated current (2 kA) the short circuit reactance by

itself provides an injected voltage (approximately 20 kV in this case). If more

inductance is switched in and/or the tap is increased, the series voltage

increases and the current through the DFC decreases (and the flow on parallel

branches increases). The operating point moves along lines parallel to the

arrows in the figure. The slope of these arrows depends on the size of the

parallel reactance. The maximum series voltage in the first quadrant is

obtained when all inductive steps are switched in and the tap is at its

maximum.

Now, assuming maximum tap and inductance, if the throughput current

decreases (due e.g. to changing loading of the system) the series voltage will

decrease. At zero current, it will not matter whether the TSC / TSR steps are

in or out, they will not contribute to the series voltage. Consequently, the

series voltage at zero current corresponds to rated PST series voltage. Next,

moving into the second quadrant, the operating range will be limited by the

line corresponding to maximum tap and the capacitive step being switched in

(and the inductive steps by-passed). In this case, the capacitive step is

approximately as large as the short circuit reactance of the PST, giving an

almost constant maximum voltage in the second quadrant.

SSSC:

SSSC emulates like a variable inductor or capacitor in series with a

transmission line and it imitates inductance or capacitive reactance in turn to

regulate effective line reactance between two ends. Series controller in

general control current injection.

4.5 UNIFIED POWER FLOW CONTROLLER:

Introduction:

It Can be a standalone controller as STATCOM and SSSC. This type of

controller is a reactive compensator with the exception of producing its own

losses.it is also recognized as “unified” controller and requires small amount

of power for DC circuit exchange occurring between the shunt-series converter.

“The UPFC is a combination of a static compensator and static series

compensation. It acts as a shunt compensating and a phase shifting device

simultaneously.”

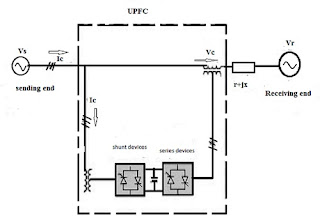

Block diagram of UPFC:

Fig 4.13: Principle configuration of an UPFC

The UPFC consists of a shunt

and a series transformer, which are connected via two voltage source converters

with a common DC-capacitor. The DC-circuit allows the active power exchange

between shunt and series transformer to control the phase shift of the series

voltage. This setup, as shown in Figure 5.1, provides the full controllability

for voltage and power flow. The series converter needs to be protected with a

Thyristor bridge. Due to the high efforts for the Voltage Source Converters and

the protection, an UPFC is getting quite expensive, which limits the practical

applications where the voltage and power flow control is required

simultaneously.

4.6 OPERATING

PRINCIPLE OF UPFC:

The basic components of the UPFC are two voltage source inverters

(VSIs) sharing a common dc storage capacitor, and connected to the power system

through coupling transformers. One VSI is connected to in shunt to the

transmission system via a shunt transformer, while the other one is connected

in series through a series transformer.

A basic UPFC functional scheme is shown in fig.5.2

Fig 4.14: a model of UPFC

The series inverter is controlled to inject a symmetrical three

phase voltage system (VSE), of controllable magnitude and

phase angle in series with the line to control active and reactive power flows

on the transmission line. So, this inverter will exchange active and reactive

power with the line. The reactive power is electronically provided by the

series inverter, and the active power is transmitted to the dc terminals. The

shunt inverter is operated in such a way as to demand this dc terminal power

(positive or negative) from the line keeping the voltage across the storage

capacitor Vdc constant. So, the net real power absorbed from the line by the

UPFC is equal only to the losses of the inverters and their transformers. The

remaining capacity of the shunt inverter can be used to exchange reactive power

with the line so to provide a voltage regulation at the connection point.

The two VSI’s can work independently of each other by separating the

dc side. So in that case, the shunt inverter is operating as a STATCOM that

generates or absorbs reactive power to regulate the voltage magnitude at the

connection point. Instead, the series inverter is operating as SSSC (static

synchronous series compensator) that generates or absorbs reactive power to

regulate the current flow, and hence the power low on the transmission line.

The UPFC has many possible operating modes. In particular, the shunt

inverter is operating in such a way to inject a controllable current, ish into

the transmission line. The shunt inverter can be controlled in two different

modes:

VAR Control Mode: The reference input is an inductive or capacitive VAR request. The

shunt inverter control translates the VAR reference into a

corresponding shunt current request and adjusts gating of the inverter to

establish the desired current. For this mode of control a feedback signal

representing the dc bus voltage, Vdc, is also required.

Automatic Voltage Control Mode: The

shunt inverter reactive current is automatically regulated to maintain the

transmission line voltage at the point of connection to a reference value. For

this mode of control, voltage feedback signals are obtained from the sending

end bus feeding the shunt coupling transformer.

The series inverter controls the magnitude and angle of the voltage

injected in series with the line to influence the power flow on the line. The

actual value of the injected voltage can be obtained in several ways.

Direct Voltage Injection Mode: The reference inputs are directly the magnitude and phase angle of

the series voltage.

Phase Angle Shifter Emulation mode: The reference input is phase displacement between the sending end

voltage and the receiving end voltage. Line Impedance Emulation mode: The reference

input is an impedance value to insert in series with the line impedance

Automatic Power Flow Control Mode: The reference inputs are values of P and

Q to maintain on the transmission line despite system changes.

CHAPTER

6

SIMULATION RESULTS

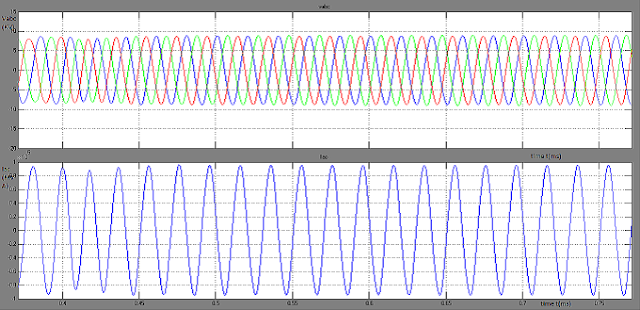

5.1 UNBALANCING PHASE VOLTAGES:

In Fig. 6, Shows HVDC system with UPFC the real power Output in the

line is controlled to obtain steady-state condition when system harmonics is

introduced. The weak power Transmission normally occurring in long transmission

lines was studied using MATALB. The diagram given in Fig. 6 shows the

computational layout of HVDC which is simulated for damping system harmonics

and rectification as well as with power inversion in its converters. Simulation

of HVDC System carried out using MATLAB / SIMULINK with UPFC and Simulation

results was presented to create oscillations with the line current and power

waveforms during the power transmission.

Fig 6.2 to Fig 6.10 shows the simulation results of HVDC system when

three phase, Line to Ground and double line ground with and without UPFC. From

the simulations results , it is observed that when different types of faults

i.e. three phase ., Line to Ground and Double Line to ground occurs the system

are having more oscillations and system takes more time to reach the steady

state operation.. By using UPFC the system reduces oscillation and thereby

enhanced the power transfer capability of HVDC system.

Fig 6.1: Simulation Result of HVDC systems

5.2 THREE-PHASE FAULT OCCURS ON INVERTER:

In Fig. 6.1, fault is created in phase A of the rectifier bus at t=0.03sec,

it results in unbalancing of the phase voltages and generates harmonic

oscillations in DC voltages and currents. The DC voltages and currents of the

rectifier are distorted and attain peak values up to 0.9 per unit and 0.016 per

unit respectively at time t=0.12sec.

Fig.6.2 Simulation Result HVDC system when three phase

fault occurs.

In Fig 6.2, it is observed that a 3-phase fault is created in the

inverter side of HVDC system. The PWM controller activates and clears the

fault. The fault clearing can be seen first by a straight line of ‘0’ voltage

between t=0.03sec to t=0.08sec. Before the fault a Vabc=0.17pu and Iabc=0.15pu.

After the fault is cleared at t=0.3sec, the recovery is slow and there are

oscillations in DC voltage and current of the magnitude 0.13pu and 0.1pu

respectively. The rectifier DC voltage and current oscillate and settles to the

prefault values in about 3 cycles after the fault is cleared on Inverter.

5.3 THREE-PHASE FAULT OCCURS ON INVERTER WITH UPFC:

Fig 6.3: Simulation Result HVDC system when three phase fault occurs

on Inverter with UPSC.

From Fig 6.3, it is observed that different types of faults i.e.,

three phase, line to ground and double line to ground is created in the

inverter side of HVDC system at t=0.15 sec. When these faults occur in the

system, it takes more time to reach the steady state operation. The PWM

controller activates and clears the fault. Further, with the addition of UPFC

the system reduces oscillations and get pure sinusoidal waveform at voltage

Vabc=0.9 p. u and current Iabc=0.95 p.u at time t=0.15 sec.

5. 4 STEADY

STATE OPERATION OF HVDC SYSTEM ON RECTIFIER SIDE:

Fig 6.4: Simulation Result

for steady state operation of HVDC system on rectifier side.

At the rectifier side, when the fault is applied at time t=0.03sec,

voltage and current magnitudes are of the order of 1pu and 1.5pu respectively

and alpha angle is equal to 7 degrees which is shown in Fig 9.If alpha angle is

changed to higher value the system takes longer time to reach steady state .If

alpha value increases, current value decreases. The waveforms obtained at

rectifier side are same for different types of faults.

5. 5 STEADY STATE OPERATION OF HVDC SYSTEM ON

INVERTER SIDE

Fig 6.5: Simulation Result for steady state operation of HVDC system

on Inverter side

At the inverter side, when the fault is applied at time

t=0.02sec,voltage and current magnitudes are of the order of 0.03pu and 0.8pu

respectively and extension angle is equal to 180 degrees which is shown in Fig

. 10. The waveforms obtained at inverter side are same for different types of

faults.

5. 6 LINE AND ACTIVE AND REACTIVE POWER OF HVDC

SYSTEM

Fig 6.6: Simulation Result

for line active and reactive powers of HVDC system

In Fig 6.6, when a fault is created at time t=0.21sec, the active

and reactive power is maintained at 800KW and 400KVAR respectively from time

t=0sec to t=0.21sec.At time t=0.27sec both active and reactive power attain

stability and becomes steady state. It is observed that no power fluctuations

occur in P and Q after t=0.27sec.By trial and error, the integral gain is set

to be 5, so that the steady state errors are reduced for P and Q.

5. 7 LINE-TO-GROUND FAULT OCCURS ON INVERTER SIDE

Fig 6.7: Simulation Result HVDC system when Line

to Ground fault occurs on Inverter side.

In Fig 6.7, it is observed that a Line to Ground fault is created in

the inverter side of HVDC system at time t=0.025sec. The PWM controller

activates and clears the fault. Before the fault a Vabc=0.14pu and

Iabc=0.013pu. After the fault is cleared at t=0.08sec, the recovery is slow and

there are oscillations in DC voltage and current of the magnitude 0.2pu and

0.05pu respectively.

5.8 LINE-TO-GROUND FAULT OCCURS ON INVERTER SIDE

WITH UPFC:

Fig 6.8: Simulation Result

HVDC system when Line to Ground fault with UPfC

From Fig 6.8,it is observed that different types of faults i.e.,

three phase, line to ground and double line to ground is created in the

inverter side of HVDC system at t=0.15 sec. When these faults occur in the

system, it takes more time to reach the steady state operation. The PWM

controller activates and clears the fault. Further, with the addition of UPFC

the system reduces oscillations and get pure sinusoidal waveform at voltage

Vabc=0.9 p. u and current Iabc=0.95 p.u at time t=0.15 sec.

5. 9 DOUBLE-TO-GROUND FAULT OCCURS ON INVERTER

SIDE

Fig.6.9 Simulation Result HVDC system when Double Line

to Ground fault occurs on Inverter side.

In Fig 14, it is observed that a Double Line to Ground fault is

created in the inverter side of HVDC system at time t=0.02sec. The PWM

controller activates and clears the fault. Before the fault a Vabc=0.17pu and

Iabc=0.15pu. After the fault is cleared at t=0.33sec, the recovery is slow and

there are oscillations in DC voltage and current of the magnitude 0.33pu and

0.1pu respectively.

5.10 DOUBLE-TO-GROUND FAULT OCCURS ON INVERTER

SIDE WITH UPFC:

Fig 6.10: Simulation Result HVDC system when Double Line

to Ground fault with UPfC

CHAPTER 6

CONCLUSION

6.1 CONCLUSIONS

According to results that UPFC improves the system performance under

the transient and the normal conditions. However, it can control the power flow

in the transmission line, effectively. With the addition of UPFC, the magnitude

of fault current reduces and oscillations of excitation voltage also reduce.

The "current margin" is essential to prevent misfire of the Thyristor

valves. DC filters and AC filters can not only eliminate the harmonic effects

but also reduce the total harmonic distortion (THD) as well. The current

waveform in the case of a conventional controller has a lot of crests and dents,

suffers from prolonged oscillations, whereas by using PWM controller, DC

current fast returns to its nominal value.

The overshoot in case of the PWM controller is slightly less than

conventional controllers. It is more economical for the HVDC transmission

system to transfer more power as the power factor is almost near to unity and

the energy loss is low UPFC, however, has shown its flexibility in easing line congestion

and promoting a more controllable flow in the lines. HVDC can be very useful

for long transmission lines.

6.2 SCOPE FOR THE FUTURE WORK:

It is more recommended in networks or interconnected lines that have

high variation of power demands and complicated network connections with

different power frequencies. UPFC in general is good for promoting line

load-ability and pool through interconnected network buses more effectively.

UPFC can be very useful for deregulated energy market as an alternative choice

for more power generation to the load area.

REFERENCES:

[1] Lee Wei Sheng, Ahmad Razani and Neelakantan Prabhakaran,

Senior Member, IEEE “Control of

High Voltage Direct Current (HVDC) Bridges for Power Transmission Systems”

Proceedings of 2010 IEEE Student Conference on Research and Development (SCOReD

2010), 13 - 14 Dec 2010, Putrajaya, Malaysia.

[2] E.M. Yap, M. Al-Dabbagh and P.C Thum,

“Using UPFC Controller in Mitigating Line Congestion for Cost-efficient Power

Delivery, “submitted at the Tencon 2005, IEEE conference, May 2005.

[3] J.W. Evan, “Interface between automation and Substation,”

Electric Power substations engineering, J.D. Macdonald, Ed. USA: CRC

Press,2003, pp. 6-1 (Chapter 6).

[4] X.-P. Zhang, "Multiterminal Voltage-Sourced Converter

Based HVDC Models for Power Flow Analysis", IEEE Transactions on Power

Systems, vol. 18, no. 4, 2004, pp.1877-1884.

[5] D J Hanson, C Horwill, B D Gemmell, D R Monkhouse,